Corner Protection--Metal Tape

Construction Steps for Metal Corner Beads in Wall Protection

I. Pre-Construction Preparation

1. Materials & Tools

- Materials: Metal corner beads (PVC-coated or aluminum alloy), crack-resistant mortar, alkali-resistant mesh (optional).

- Tools: Level, trowel, scissors, mixer, chalk line.

2. Surface Preparation

- Check wall corners for verticality (using a 2m straightedge). If deviation >3mm, level with cement mortar.

- Remove dust and oil stains, pre-moisten the surface (no standing water).

II. Construction Steps

1. Layout & Marking

Illustration:

- Snap chalk lines to mark corner bead installation positions.

- Note: Priority installation at door/window openings and high-impact areas.

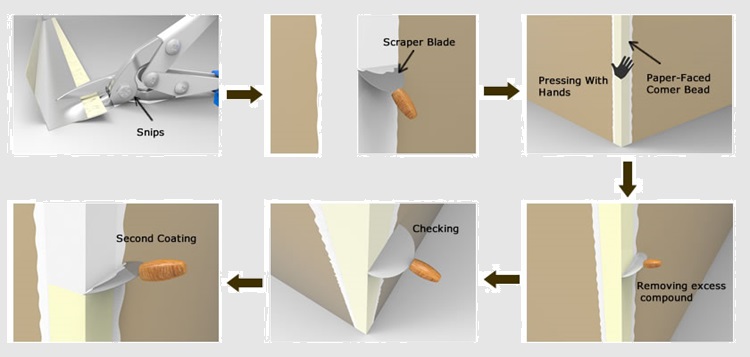

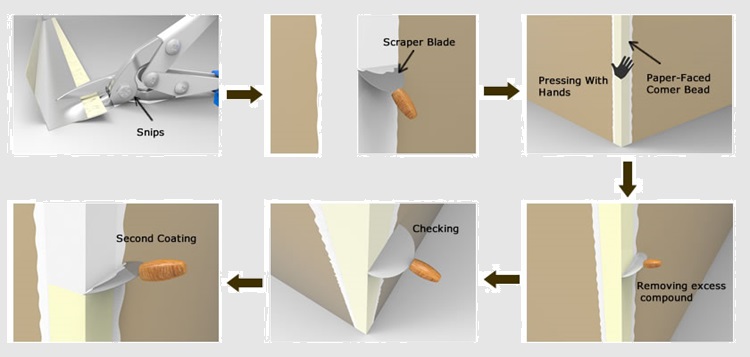

2. Cutting Corner Beads

Illustration:

- Cut corner beads to wall height (typically 2.4m lengths), with 45° miter cuts for seamless joints.

3. Applying Mortar

Illustration:

- Apply crack-resistant mortar (3-5mm thick) to the back of the corner bead and wall corner.

4. Installing Corner Beads

Illustration:

- Press the corner bead into the mortar, adjusting for plumb/level using a level.

- Key Point: Ensure full mortar contact, no hollow spots.

5. Reinforcement & Coverage

Illustration:

- Option 1 (Standard)**: Embed alkali-resistant mesh (≥100mm width) over the bead edges, then apply finish mortar.

- Option 2 (High Strength): Secure corner beads with nails or anchors (spacing ≤300mm), then cover with mortar.

6. Finishing

Illustration:

- Smooth mortar from the corner bead outward, blending with the wall surface.

- Note: Total thickness should match wall plaster (typically 5-7mm).

III. Key Details (Illustrations)

1. External Corner Installation: Show 90° alignment with full mortar coverage.

2. Internal Corner Treatment**: Embed bead and finish with a corner trowel.

3. Joint Connection: Leave 2mm gap between bead ends, fill with mortar to prevent cracking.

IV. Important Notes

1. Environmental Conditions: Minimum 5°C, no work during rain.

2. Quality Control:

- Avoid impacts on installed beads for 24 hours.

- Prevent rapid drying (water spray curing for 1-2 days).

3. Safety, Use harnesses for elevated work; wear gloves when cutting beads.

V. Troubleshooting

- Bead Warping: Caused by insufficient mortar or poor compaction—reinstall.

- Surface Cracks: Check mortar mix ratio (cement:sand = 1:2.5) or curing practices.

Attached: Construction Flow Diagram

For detailed illustrations (e.g., bead fastening methods, mortar application techniques), specify requirements for further refinement.

I. Pre-Construction Preparation

1. Materials & Tools

- Materials: Metal corner beads (PVC-coated or aluminum alloy), crack-resistant mortar, alkali-resistant mesh (optional).

- Tools: Level, trowel, scissors, mixer, chalk line.

2. Surface Preparation

- Check wall corners for verticality (using a 2m straightedge). If deviation >3mm, level with cement mortar.

- Remove dust and oil stains, pre-moisten the surface (no standing water).

II. Construction Steps

1. Layout & Marking

Illustration:

- Snap chalk lines to mark corner bead installation positions.

- Note: Priority installation at door/window openings and high-impact areas.

2. Cutting Corner Beads

Illustration:

- Cut corner beads to wall height (typically 2.4m lengths), with 45° miter cuts for seamless joints.

3. Applying Mortar

Illustration:

- Apply crack-resistant mortar (3-5mm thick) to the back of the corner bead and wall corner.

4. Installing Corner Beads

Illustration:

- Press the corner bead into the mortar, adjusting for plumb/level using a level.

- Key Point: Ensure full mortar contact, no hollow spots.

5. Reinforcement & Coverage

Illustration:

- Option 1 (Standard)**: Embed alkali-resistant mesh (≥100mm width) over the bead edges, then apply finish mortar.

- Option 2 (High Strength): Secure corner beads with nails or anchors (spacing ≤300mm), then cover with mortar.

6. Finishing

Illustration:

- Smooth mortar from the corner bead outward, blending with the wall surface.

- Note: Total thickness should match wall plaster (typically 5-7mm).

III. Key Details (Illustrations)

1. External Corner Installation: Show 90° alignment with full mortar coverage.

2. Internal Corner Treatment**: Embed bead and finish with a corner trowel.

3. Joint Connection: Leave 2mm gap between bead ends, fill with mortar to prevent cracking.

IV. Important Notes

1. Environmental Conditions: Minimum 5°C, no work during rain.

2. Quality Control:

- Avoid impacts on installed beads for 24 hours.

- Prevent rapid drying (water spray curing for 1-2 days).

3. Safety, Use harnesses for elevated work; wear gloves when cutting beads.

V. Troubleshooting

- Bead Warping: Caused by insufficient mortar or poor compaction—reinstall.

- Surface Cracks: Check mortar mix ratio (cement:sand = 1:2.5) or curing practices.

Attached: Construction Flow Diagram

For detailed illustrations (e.g., bead fastening methods, mortar application techniques), specify requirements for further refinement.